Solutions

Balance of Stack

Balance of Stack refers to the complete and optimized integration of all components in an energy or industrial system, ensuring that each part of the system operates efficiently to achieve the desired outcome.

It involves the supporting systems that are outside the electrolyzer stack & are essential for the functioning of the entire system. It includes all the auxiliary systems that support the core hydrogen-generating unit, making it the backbone of a reliable and scalable Green Hydrogen infrastructure.

Balance of Stack Solutions

- Water Management & Purification: Supplying high-purity water essential for electrolysis while optimizing water use and recovery.

- Power Conditioning Systems: Managing steady power to the electrolyzer, often leveraging renewable sources.

- Electrolyte Circulation (Closed Loop) System: Electrolyte is supplied using a closed loop circulation system to feed stack. Electrolyte is duly reconditioned so as to meet stack operational parameters.

- Gas Moisture Separation System: Both hydrogen and oxygen generated in the stack are saturated with moisture. The gases are separated from the liquid (moisture) based on gravity. This separation takes place in the process skid, which includes H₂/O₂ separators, washers, a scrubber, demister, heat exchanger, and other components. The residence time is carefully designed to allow gas bubbles to rise and exit into the gas phase efficiently.Both hydrogen and oxygen generated in the stack are saturated with moisture. The gases are separated from the liquid (moisture) based on gravity. This separation takes place in the process skid, which includes H₂/O₂ separators, washers, a scrubber, demister, heat exchanger, and other components. The residence time is carefully designed to allow gas bubbles to rise and exit into the gas phase efficiently.

- Hydrogen Purification & Drying Unit (HPDU): Hydrogen gas moves from Gas Moisture Separation unit to HPDU in deoxo reactor consisting of catalyst bed where oxygen impurity is removed by virtue of deoxo reaction in presence of catalyst. The pure gas is dried using Nuberg Temperature Swing Adsorption (TSA) technology-based Dryer system (One tower in working condition and one tower under regeneration). The product Hydrogen leave HPDU as per designed purity & dew point parameters.

- Safety & Monitoring Systems: Incorporating real-time data analytics, leak detection, and emergency shutdown tools or systems in case of emergency to ensure safe, continuous operation.

Nuberg offers Green Hydrogened - HPDU systems from 1 MW to 100 MW (Single unit) based on its proprietary DEOXO & TSA technology. Unlike traditional 24x7 HPDU systems requiring continuous H₂ availability, Nuberg G-HPDU is specially designed to meet challenges of Intermittent RE power availability in Green Hydrogen Plants.

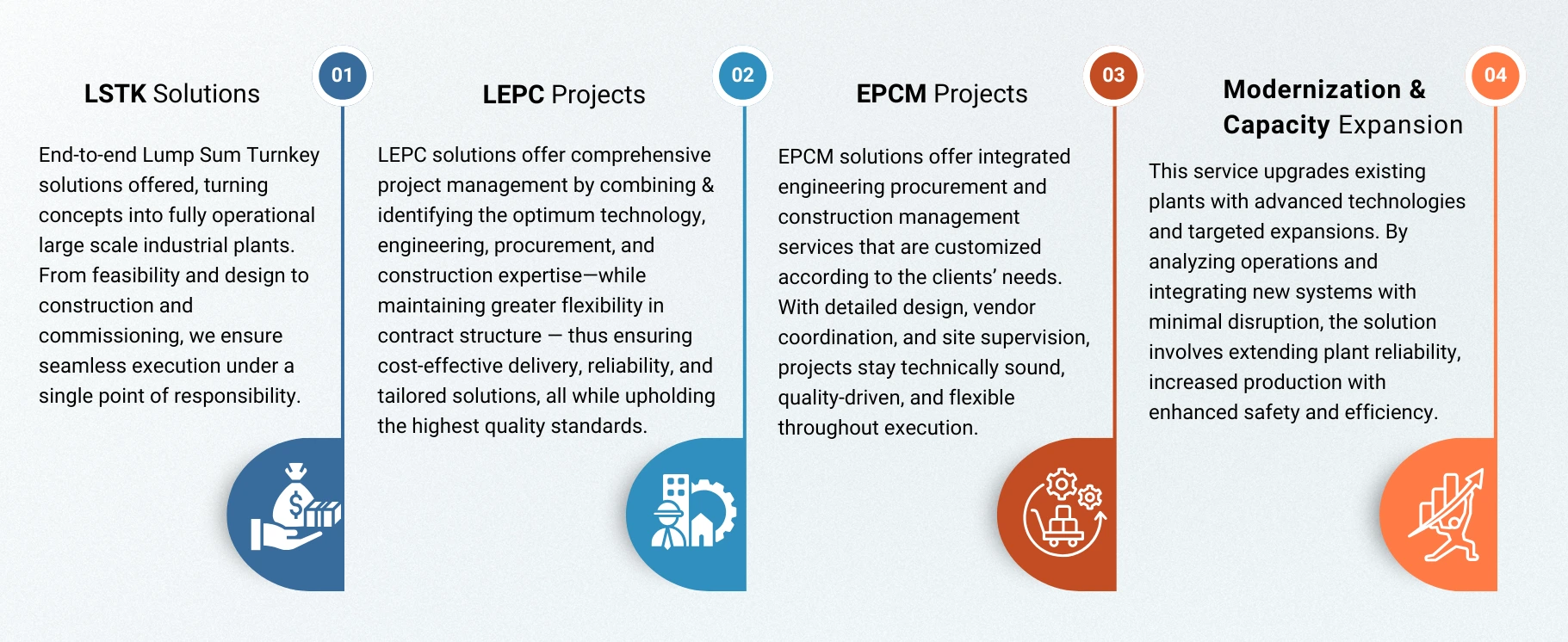

Services

Proven Track Record

- Successfully commissioned 350 Nm³/Hr Green Hydrogen Plant – Balance of Stack for Hygenco Green Energy in Hissar, India.

- Executed 200 Nm³/Hr Hydrogen Purification & Drying Unit project for Linde in West India.

- Delivered 30 Nm³/Hr H₂ Balance of Stack project for Bhabha Atomic Research Centre (BARC) in Maharashtra, India.

Visit the link to explore full project portfolio of Balance of Stack: Nuberg Green Energy Projects